English GB

EUR €

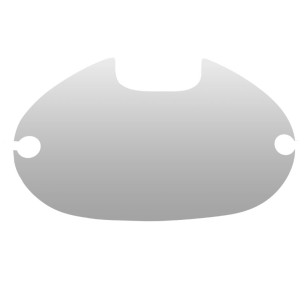

Mineral Inactive Glass, 110x55 tones 09-14

71600

Ok!

See welding, not the risk.

· Ref. 71600

· Mineral glass welding filters.

· Size 110x55 mm DIN 9/14

· Identified by their grade number from 9 to 14 and by size.

· Made of mineral molten glass smoked in the mass and protect eyes against welding rays.

· Laser cut polished.

· Ref. 71600

· Mineral glass welding filters.

· Size 110x55 mm DIN 9/14

· Identified by their grade number from 9 to 14 and by size.

· Made of mineral molten glass smoked in the mass and protect eyes against welding rays.

· Laser cut polished.

Reliable eye protection for welding with inactive mineral glass 110x55, available in DIN shades 9 to 14.

Laser cut polished for superior clarity and durability, with excellent value for money.

Optimise your safety and performance with inactive mineral glass 110x55. Its DIN shade range 914 adapts to multiple welding processes, offering consistent protection against arc radiation. The laser cut polished provides precise edges for a secure fit in the screen and a clean visibility without distortions. Made of mineral molten glass smoked in the mass, it ensures optical stability, heat resistance, and long life span.

Usage suggestions: select the DIN shade based on amperage and process (MMA, MIG/MAG, TIG) to balance protection and visibility; keep the glass clean with non-abrasive cloths; check the fit in the filter holder to avoid light leaks.

See welding, not the risk.

Use Cases:

- MMA/Stick welding in industrial maintenance with DIN shades 1012

- MIG/MAG welding in metal fabrication and boilermaking with DIN shades 1113

- TIG welding in precision jobs with DIN shades 912

Laser cut polished for superior clarity and durability, with excellent value for money.

Optimise your safety and performance with inactive mineral glass 110x55. Its DIN shade range 914 adapts to multiple welding processes, offering consistent protection against arc radiation. The laser cut polished provides precise edges for a secure fit in the screen and a clean visibility without distortions. Made of mineral molten glass smoked in the mass, it ensures optical stability, heat resistance, and long life span.

Usage suggestions: select the DIN shade based on amperage and process (MMA, MIG/MAG, TIG) to balance protection and visibility; keep the glass clean with non-abrasive cloths; check the fit in the filter holder to avoid light leaks.

See welding, not the risk.

Use Cases:

- MMA/Stick welding in industrial maintenance with DIN shades 1012

- MIG/MAG welding in metal fabrication and boilermaking with DIN shades 1113

- TIG welding in precision jobs with DIN shades 912

- Packaging unit

- 10/100 pcs

- EN166

- OK

- EN169

- OK