English GB

EUR €

ECAP, Arc Flash Kit, 80540 +79046+79745+79746(2)

81540

Ok!

One kit, total protection against arc flash.

· Electrical protection.

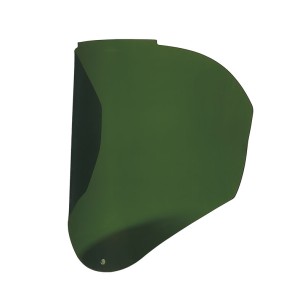

· Combination of face and head protection.

· Designed for industrial applications.

· Long flip-up frontal coverage area.

· High impact class A protection.

· UV protection.

· Protection against drops and splashes of liquids.

· Protection against numerous solvents, molten metals and hot solids (9).

· Protection against liquid nitrogen and high temperatures.

· Does not cause visual fatigue or distortion in vision or colours.

· The helmet is certified against 1000V electrical risk, and also has LD marking (lateral deformation resistance) and very low temperatures (-30ºC).

· Electrical protection.

· Combination of face and head protection.

· Designed for industrial applications.

· Long flip-up frontal coverage area.

· High impact class A protection.

· UV protection.

· Protection against drops and splashes of liquids.

· Protection against numerous solvents, molten metals and hot solids (9).

· Protection against liquid nitrogen and high temperatures.

· Does not cause visual fatigue or distortion in vision or colours.

· The helmet is certified against 1000V electrical risk, and also has LD marking (lateral deformation resistance) and very low temperatures (-30ºC).

Comprehensive head and face protection against arc flash, impacts and splashes in a single kit.

Differentiator: 1000 V certification, high impact class A visor and wrap-around coverage without visual fatigue.

The ECAP, Arc Flash Kit, brings together in one set the head and facial protection required by modern industry. Its class A visor offers high impact and UV protection, with wide flip-up coverage for safe and comfortable work. Distortion-free optics reduce visual fatigue during long shifts, maintaining precise panoramic vision. Designed for demanding environments, it protects against liquid splashes, numerous solvents, molten metals and hot solids (9), while also resisting liquid nitrogen and extreme temperatures. The helmet is certified for 1000 V electrical risk, with LD marking and reliable performance at -30 ºC, ensuring quality and durability in intensive use. Recommended for electrical manoeuvres, industrial maintenance and operations in chemical or metallurgy plants. A professional solution that combines technology, quality and ergonomics with excellent value for money.

Use cases:

- Maintenance and manoeuvres in electrical panels up to 1000 V in industrial environments.

- Operations in substations and transformation centres with risk of arc flash and impact.

- Work in chemical plants, metallurgy and laboratories with liquid nitrogen and high temperatures.

Differentiator: 1000 V certification, high impact class A visor and wrap-around coverage without visual fatigue.

The ECAP, Arc Flash Kit, brings together in one set the head and facial protection required by modern industry. Its class A visor offers high impact and UV protection, with wide flip-up coverage for safe and comfortable work. Distortion-free optics reduce visual fatigue during long shifts, maintaining precise panoramic vision. Designed for demanding environments, it protects against liquid splashes, numerous solvents, molten metals and hot solids (9), while also resisting liquid nitrogen and extreme temperatures. The helmet is certified for 1000 V electrical risk, with LD marking and reliable performance at -30 ºC, ensuring quality and durability in intensive use. Recommended for electrical manoeuvres, industrial maintenance and operations in chemical or metallurgy plants. A professional solution that combines technology, quality and ergonomics with excellent value for money.

Use cases:

- Maintenance and manoeuvres in electrical panels up to 1000 V in industrial environments.

- Operations in substations and transformation centres with risk of arc flash and impact.

- Work in chemical plants, metallurgy and laboratories with liquid nitrogen and high temperatures.

- Packaging unit

- EN166

- OK

- Frame resistance

- 1AT89

- High temperature

- OK

- EN397

- OK

- EN50365

- OK

You might also like

Customers who bought this product also bought:

Flame-resistant technical clothing

ARAPRO, multi-protection navy blue jacket with reflective tape

Ref. 135