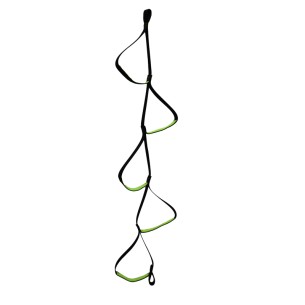

Lifeline 50 m, absorber+lanyard+carabiners 12mm

· 12 mm diameter polyester lifeline, with non-removable lanyard, two hook carabiners and energy absorber.

· Both carabiners Ref. 80111, with 19 mm opening and 20 Kn resistance.

· Non-removable mini energy absorber with dimensions 230x34x32 mm.

· Ends manufactured with thimbles.

· Available in different lengths:

- 40 m (Ref. 80234)

- 50 m (Ref. 80235)

- 70 m (Ref. 80237)

- 80 m (Ref. 80238)

Its differential: non-removable lanyard, 80111 carabiners of 20 Kn and thimbled ends for durability and reliability.

Designed for demanding work at heights, this 50 m lifeline combines a 12 mm polyester rope with an integrated mini energy absorber to effectively manage loads in the event of a fall. The non-removable lanyard facilitates sliding and progression, while the hook carabiners Ref. 80111 (19 mm opening, 20 Kn) ensure quick and secure anchoring. Thimbled ends increase resistance to wear, prolonging the life of the set.

Its design prioritises quality and reliability, maintaining an excellent quality-price ratio to provide your team with a complete, ready-to-use solution. Ideal for temporary or semi-permanent lines, it offers control, ergonomics and performance in every section of work.

Usage suggestions: check anchoring points before each installation, keep the line free from sharp edges and plan the length to optimise the path and minimise slack.

Use cases:

- Installation and maintenance on roofs and facades (construction and refurbishment).

- Work on metal structures, catwalks and industrial buildings.

- Assembly and maintenance of antennas, towers and utility lines.

- Packaging unit

- EN353-2

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.