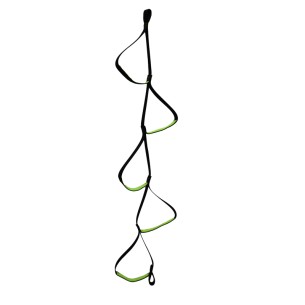

Roll-Up Rope Ladder, 11 m and 37 rungs

· 11 meter ladder.

· 37 rungs.

· United by parallel polyamide ropes.

· Aluminium rungs fixed through aluminium staples.

· Attachment knots with thimbles.

· For fastening the rope to anchoring points.

· Rollable and easy to transport.

· Constructed with 8 mm wide polyamide rope.

· Distance between rungs: 31 cm.

· Width of each rung: 31 cm.

· Aluminium dimensions: 25x15x310 mm.

· The admitted working load is 120 kg.

· APPLICATIONS Can be used as an auxiliary device during the execution of height work when moving (up and down) in a vertical direction.

Parallel polyamide ropes and aluminium rungs with staples: stability, durability and easy transport (120 kg load).

Optimise your vertical manoeuvres with a solution designed for the demanding professional. Its configuration of parallel polyamide ropes and aluminium rungs secured with staples offers an exemplary balance between strength, stability and lightness. The 31 cm spacing between rungs promotes an ergonomic climbing rhythm, while the roll-up format simplifies transport and storage in vehicles or site sheds. With 11 metres of reach and 37 rungs, it is ideal as an auxiliary device for temporary access, inspections and maintenance tasks where rapid deployment and safety make the difference. The construction with 8 mm rope and an admitted working load of 120 kg reinforces its reliability in industrial and construction environments. An outstanding value for money for teams needing performance without complications.

Use cases:

- Maintenance and inspections on roofs, silos and industrial buildings.

- Temporary access to towers, scaffolds, tanks and elevated spaces.

- Emergency operations, rescue and controlled evacuation on site or plant.

- Packaging unit

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.