AIFLOW WELD-NEW, PR010 New model 4 breathing equipment TH3 PR SL Welding

70600-N

Breathe safely, weld without limits.

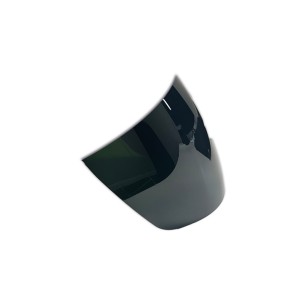

· Welding screen with transparent visor providing a clear and wide view for precision work.

· Integrated respiratory protection unit with welding helmet, designed for environments with hazardous particles.

· Adjustable airflow in three levels: 170, 210, and 250 litres per minute.

· Integrated rechargeable battery with charge indicator and low battery or clogged filter alarm.

· TH3 P R SL protection level, with 99.98% filtration efficiency against solid and liquid particles.

· High-performance filters with multi-layer technology, easily replaceable.

· Ergonomic and balanced design, intended to minimise fatigue in prolonged use.

· Resistant and comfortable hood, made of polyurethane, polyethylene, and polycarbonate, compatible with welding.

· ABS bayonet type connection, ensuring a firm and secure joint of the breathing tube.

· Durable and resistant materials, such as ABS, polypropylene, and stainless steel in structural components.

· Complies with DIN EN 175:1997-08 standard, relating to eye and face protection in welding processes.

· High compatibility with demanding industrial applications, including welding, metallurgy, construction, and chemistry.

· Extended autonomy: up to 11 hours on low flow and 6 hours on high flow.

· Welding screen with transparent visor providing a clear and wide view for precision work.

· Integrated respiratory protection unit with welding helmet, designed for environments with hazardous particles.

· Adjustable airflow in three levels: 170, 210, and 250 litres per minute.

· Integrated rechargeable battery with charge indicator and low battery or clogged filter alarm.

· TH3 P R SL protection level, with 99.98% filtration efficiency against solid and liquid particles.

· High-performance filters with multi-layer technology, easily replaceable.

· Ergonomic and balanced design, intended to minimise fatigue in prolonged use.

· Resistant and comfortable hood, made of polyurethane, polyethylene, and polycarbonate, compatible with welding.

· ABS bayonet type connection, ensuring a firm and secure joint of the breathing tube.

· Durable and resistant materials, such as ABS, polypropylene, and stainless steel in structural components.

· Complies with DIN EN 175:1997-08 standard, relating to eye and face protection in welding processes.

· High compatibility with demanding industrial applications, including welding, metallurgy, construction, and chemistry.

· Extended autonomy: up to 11 hours on low flow and 6 hours on high flow.

Protect your airways with TH3 P R SL level (99.98% filtration) while enjoying a wide and clear view for precision welding. Adjustable airflow technology and balanced ergonomics for long workdays with maximum comfort and productivity.

AIFLOW WELD-NEW, UN-PR03 combines TH3 P R SL respiratory protection (99.98% filtration) with a high-visibility welding screen to execute high-precision jobs. Its adjustable airflow technology (170/210/250 l/min) and low battery/obstruction alarm ensure operational continuity and weld quality even on long shifts.

Designed for productivity: balanced ergonomics that reduce fatigue, high-strength materials (ABS, PP, and stainless steel), and quick-change multi-layer filters to minimise downtime. Complies with DIN EN 175:1997-08 and performs in environments with solid and liquid particles, from workshops to construction sites and chemical plants.

Usage suggestions:

- Select the flow rate according to the type of process and ambient temperature to maintain thermal comfort and visibility.

- Plan your workday with autonomy: up to 11 h on low flow and 6 h on high; keep spare filters handy.

- Check the bayonet connection and hood seal before entering high particulate load areas.

AIFLOW WELD-NEW: breathe safely, weld without limits.

Use cases:

- MIG/MAG/TIG welding and electrode in workshops and production lines with high fume and particle generation.

- Maintenance and repair in metallurgical and chemical plants where TH3 protection against aerosols is required.

- Construction and assembly work in the field with grinding, cutting, and tack welding, prioritising visibility and autonomy.

AIFLOW WELD-NEW, UN-PR03 combines TH3 P R SL respiratory protection (99.98% filtration) with a high-visibility welding screen to execute high-precision jobs. Its adjustable airflow technology (170/210/250 l/min) and low battery/obstruction alarm ensure operational continuity and weld quality even on long shifts.

Designed for productivity: balanced ergonomics that reduce fatigue, high-strength materials (ABS, PP, and stainless steel), and quick-change multi-layer filters to minimise downtime. Complies with DIN EN 175:1997-08 and performs in environments with solid and liquid particles, from workshops to construction sites and chemical plants.

Usage suggestions:

- Select the flow rate according to the type of process and ambient temperature to maintain thermal comfort and visibility.

- Plan your workday with autonomy: up to 11 h on low flow and 6 h on high; keep spare filters handy.

- Check the bayonet connection and hood seal before entering high particulate load areas.

AIFLOW WELD-NEW: breathe safely, weld without limits.

Use cases:

- MIG/MAG/TIG welding and electrode in workshops and production lines with high fume and particle generation.

- Maintenance and repair in metallurgical and chemical plants where TH3 protection against aerosols is required.

- Construction and assembly work in the field with grinding, cutting, and tack welding, prioritising visibility and autonomy.

- Packaging unit

- EN166

- OK

- EN12941

- OK

- TH3

- OK