English GB

EUR €

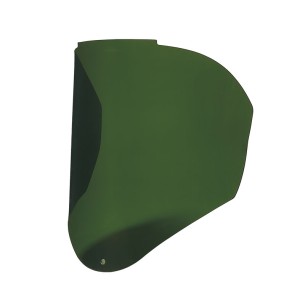

SUPERFACE VISOR, DIN5 welding with aluminium ring, 1B T 3

79355

Ok!

Protection that you can see.

· DIN5 for welding work with low darkening level

· Aluminium ring

· 1B T 3 marking

· Replacement visor compatible with Superface Green (ref. 79350)

· Ref. 79355

· DIN5 for welding work with low darkening level

· Aluminium ring

· 1B T 3 marking

· Replacement visor compatible with Superface Green (ref. 79350)

· Ref. 79355

Reliable protection and clear vision for welding tasks with low DIN5 darkening. Aluminium ring and 1B T 3 marking: sturdiness, impact/splash resistance, and temperature performance.

The SUPERFACE DIN5 VISOR is designed for the professional who needs clear vision and effective protection in welding and heating tasks with low light intensity. Its aluminium ring provides rigidity and durability, while the 1B T 3 marking ensures an optimal balance between optical clarity, impact resistance, and splash protection. As a replacement visor for the Superface Green system (ref. 79350), it integrates easily, optimising equipment maintenance and reducing downtime. Ideal for demanding environments where quality and ergonomics make the difference. Usage suggestions: keep the visor clean to maximise visibility, check the ring fit to ensure splash sealing, and combine the visor with the compatible screen for comprehensive protection.

Use cases:

- Oxyacetylene welding, brazing, and torch heating (low intensity)

- Thermal cutting operations and industrial maintenance with splash risk

- Inspection and preparation works where low attenuation and high clarity are required

The SUPERFACE DIN5 VISOR is designed for the professional who needs clear vision and effective protection in welding and heating tasks with low light intensity. Its aluminium ring provides rigidity and durability, while the 1B T 3 marking ensures an optimal balance between optical clarity, impact resistance, and splash protection. As a replacement visor for the Superface Green system (ref. 79350), it integrates easily, optimising equipment maintenance and reducing downtime. Ideal for demanding environments where quality and ergonomics make the difference. Usage suggestions: keep the visor clean to maximise visibility, check the ring fit to ensure splash sealing, and combine the visor with the compatible screen for comprehensive protection.

Use cases:

- Oxyacetylene welding, brazing, and torch heating (low intensity)

- Thermal cutting operations and industrial maintenance with splash risk

- Inspection and preparation works where low attenuation and high clarity are required

- Packaging unit

- EN166

- OK

- EN170 (UV)

- OK

- Frame resistance

- 1BT3

- Lens filter type

- 5 (welding)

Customers who bought this product also bought:

16 other products in the same category:

Customers who bought this product also bought:

Head protection

MONTANA, Dielectric Helmet EN397, EN50365 with Chin Strap and Clear Visor

Ref. 80640-E