ANCHOR SET for SLOPES complete with Surface Enhancer for Loosely Compacted Grounds

· Anchor for earth slopes, complete.

· Includes surface enhancer, for loosely compacted grounds.

The ANCHOR SET for SLOPES complete with Surface Enhancer is designed to offer reliable stabilisation in projects where soil conditions require precise solutions. Being a complete set, it reduces provisioning times and unexpected site delays, facilitating orderly and efficient installation. Its integrated surface enhancer improves load distribution on loosely compacted surfaces, enhancing adhesion and anchor performance during critical containment stages.

Focusing on Technology and Quality, this set prioritises consistent results and a competitive price-quality ratio for road, urban, and industrial works. It is the technical choice when seeking safety, performance, and operational simplicity in one package.

Usage suggestions:

- Conduct prior geotechnical verification and define the anchor pattern according to structural calculation.

- Prepare the slope surface, remove loose material and position the surface enhancer to ensure effective contact.

- Apply design tension and complement with meshes, geomats, or projections (as per project) for an integral system.

- Schedule periodic inspections and tension recordings to ensure performance over time.

Use cases:

- Stabilisation of slopes in road and rural path cuttings

- Containment and protection of slopes in urbanisations and industrial parks

- Temporary or permanent support in excavations with loosely compacted soils

- Packaging unit

- EN795

- OK

Is the inspection of fall-arrest PPE mandatory?

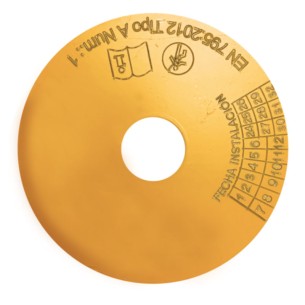

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.