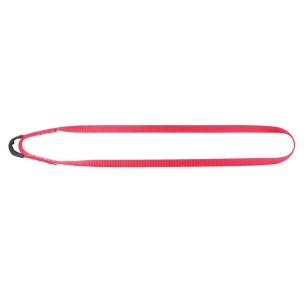

1.5 m polyester rope with thimbles, without carabiners

· Polyamide braided rope in yellow-black colour for easy visibility.

· Lashing or fixing element in a work position.

· Total length (from thimble to thimble): 1.5 m.

· Diameter: 12 mm.

· Made of polyamide/polyester.

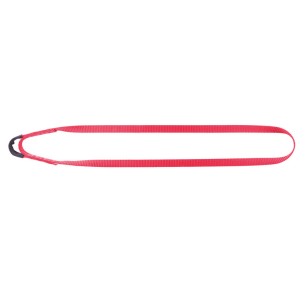

· Ends manufactured with heat-sealed and internally reinforced loops for carabiner connection.

· Carabiners must be certified according to EN362 standard.

· Available in 1 m (Ref. 80102) and in 1.5 m (Ref. 80105-SM).

High visibility yellow-black finish, compatible with EN362 carabiners for reliable technical use.

Maximise safety and order in your lashing and positioning tasks with a high-performance rope. Its polyamide braiding with polyester reinforcement offers an optimal combination of strength, flexibility, and durability, while the yellow-black design ensures immediate visibility on site or plant. The thimbles with heat-sealed and reinforced loops protect the connection area, extending the lifespan of the assembly and facilitating the use with EN362 certified carabiners.

Designed for professionals demanding quality and efficiency, its 12 mm diameter provides a comfortable and controlled grip, and its 1.5 m length is ideal for close anchoring points and precise positioning. Excellent value for money and compatibility with a wide range of certified accessories.

Suggestions: use it as a temporary fixing element, for positioning on structures, and to secure components during maintenance, always with suitable EN362 carabiners.

Visible hold, total confidence.

Use cases:

- Work positioning on structures, railings, or temporary lifelines (with EN362 carabiners).

- Fixing and securing components or tools in industrial maintenance and height assembly.

- Construction and scaffolding work requiring high visibility and lashing control.

- Packaging unit

- EN354

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.