CLAW ANCHORAGE, anchoring bar for aluminium beams

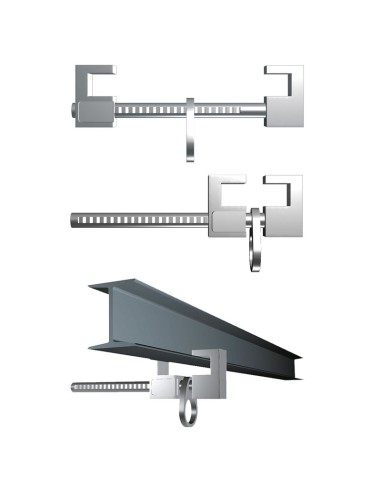

· Composed of a cylindrical structure with 23 teeth providing distances between the two claws from 90 to 400 mm.

· Two claws, one mobile and the other fixed at one end of the cylinder.

· On one face of the mobile claw, there is a latch that, after being pressed, allows the change in distance between the claws.

· A cylindrical piece that acts as the operator's anchoring element.

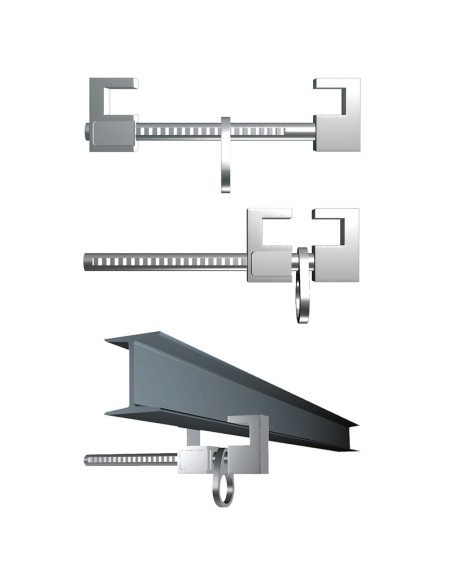

· APPLICATIONS Anchoring device to adapt to aluminium beams.

Its design with 23 notched positions and release latch facilitates agile and reliable changes on site.

Maximise safety and productivity in work on aluminium beams with this claw anchorage. Its robust and quality design integrates two claws (mobile and fixed) and an easy-to-operate latch that allows precise adjustment of the gap between 90 and 400 mm thanks to 23 notched positions. The cylindrical anchoring point offers a direct and reliable connection for the operator, reducing assembly times and errors.

Ideal for technical teams seeking a versatile solution with excellent value for money, combining practical design and durability in assembly, maintenance and temporary installation environments.

Adjust, anchor and work safely.

Use cases:

- Assembly and maintenance on roofs or structures with aluminium beams.

- Temporary installations in events, stage sets or fairs with aluminium profiles.

- Repair and inspection work in industrial buildings with aluminium frameworks.

- Packaging unit

- EN795B

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.