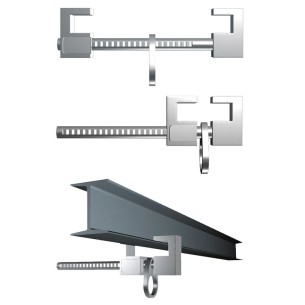

PERMANENT ANCHOR SET, 30 kN for installing on concrete

· Composed of 135x140 mm steel plate + 240x440 mm concrete anchor plate and 6 anchor screws (included).

· Position of use: vertical, horizontal, and inclined.

· Specially designed for use with Ref. 80266 (horizontal lifeline), when used by 3 operators at the same time anchored to concrete structures.

· Reaches 30 kN resistance.

· APPLICATIONS These type A anchors must be permanently fixed to a structure: vertical, horizontal, and inclined surfaces such as walls, columns, lintels, etc.

Robust steel design and compatibility with lifeline Ref. 80266 for working with up to 3 operators with full safety.

Designed for demanding environments, this permanent anchor set ensures a reliable anchorage point on concrete thanks to its steel plate and included fasteners. Its versatility for installation in vertical, horizontal, or inclined positions optimises installation in construction and maintenance. It stands out for its constructive quality and compatibility with lifeline Ref. 80266, allowing simultaneous operations of up to 3 users, which enhances productivity with total risk control. Excellent value for money for construction projects, industry, and height maintenance.

Usage suggestions: install it on roofs, walls, columns or lintels; use it as a terminal or intermediate point of a horizontal lifeline; verify substrate and tightening torque according to good anchoring practices.

30 kN strength, permanent confidence.

Use cases:

- Installation of horizontal lifelines on concrete roofs for maintenance work.

- Anchor point on walls and columns of industrial buildings for safe access at height.

- Fixing on lintels and slabs during civil works and structure assemblies.

- Packaging unit

- EN795A

- OK

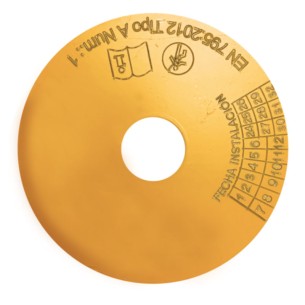

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.