RESCUE DEVICE Safetop AS Series 35 m and 140 kg load for tripod 80371-AS

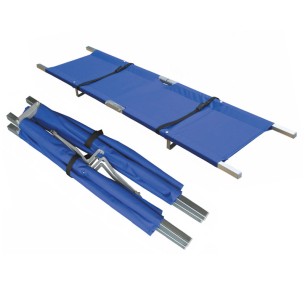

Rescue device for use with the 80371-AS tripod.

· 1 user

· Valid for maximum load 140 Kg.

· 5:1 gear ratio.

· Winch cable: Ø 5 mm stainless steel.

· Carabiner with drop indicator

Available in 15 (80315-AS), 25 (80325-AS), and 35 metres (80335-AS).

The RESCUE DEVICE Safetop AS Series 35 m is designed to operate in total synchrony with the 80371-AS tripod, offering a reliable lifting and lowering system for a user of up to 140 kg. Its 5:1 gear ratio provides smooth and precise operation, minimising operator fatigue and increasing safety in every manoeuvre. The Ø 5 mm stainless steel cable ensures corrosion resistance and durability in demanding environments, while the carabiner with drop indicator enables quick visual checking of the equipment's state before entering service. Selling points: efficient drive technology, high-quality materials, and direct compatibility with the 80371-AS tripod, within a versatile catalogue (15, 25, and 35 m) with excellent value for money. Usage suggestions: check the drop indicator before each operation, keep the cable clean and adequately lubricated, and practise lifting/lowering manoeuvres with simulated loads to ensure smooth response in emergencies.

Use cases:

- Rescue in confined spaces in industrial plants, tanks, and sewers with tripod 80371-AS.

- Access and evacuation operations in wells and underground chambers.

- Emergency support for work at heights during infrastructure maintenance.

- EN1496

- OK

- AS SERIES

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.