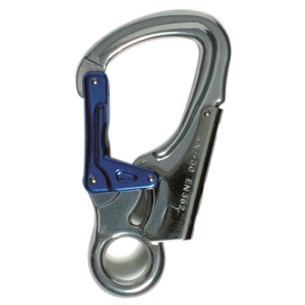

CARABINER SEMIMAXI, automatic steel with 50 mm gate

· Ref. 80113J

· Automatic locking carabiner made of silver steel.

· Used as a component and designed for direct attachment to a specific type of anchor.

· Suitable for completing a fall arrest system.

· Minimum static resistance: 25 Kn.

· Gate: 50 mm.

· APPLICATIONS Class A anchor connector: automatic locking connector. Used as a component and designed for direct attachment to a specific type of anchor. For example, as a rope anchor, harness, etc.

Its large gate and minimum strength of 25 Kn distinguish it for bulky anchor points and intensive use in fall arrest systems.

The SEMIMAXI CARABINER offers immediate and reliable connection thanks to its automatic locking and silver steel construction. Its 50 mm gate speeds up direct anchoring to large section points, reducing manoeuvre times and handling errors.

Designed for demanding work, it provides quality and durability with a minimum static resistance of 25 Kn. Its large gate ergonomics improve operability with gloves and in hard-to-access environments, maintaining an excellent quality-price ratio for completing fall arrest systems.

Usage suggestions: connect it to class A anchors, lifelines, and large diameter structures; integrate with harnesses and ropes where automatic locking is required; ideal for construction, industrial maintenance, energy and telecommunications.

Large gate, uncompromising safety.

Usage cases:

- Direct connection to class A anchors, lifelines and large diameter structures

- Integration as a connector in harnesses and restraint systems for working at heights

- Maintenance operations in industrial, construction, wind energy, and telecommunications

- Packaging unit

- EN362

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.

You might also like