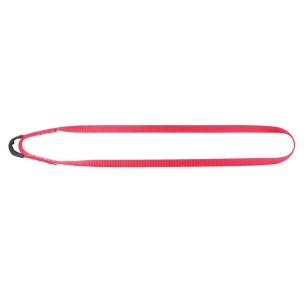

HORIZONTAL LIFE LINE 30 m, polyester 10.5 mm with carabiner

· Polyester rope 10.5 mm, considered a transportable anchoring device (anchoring device class B).

· Fully cylindrical: slides any element over it.

· At one end, non-removable carabiner 80111, with 19 mm opening and 20 Kn resistance.

· The other end free for ballast connection.

· Available in several lengths:

-5 m (Ref. 80250)

-10 m (Ref. 80251)

-20 m (Ref. 80252)

-30 m (Ref. 80253)

Fully cylindrical design and integrated carabiner 80111 (19 mm, 20 Kn) streamline the installation as a transportable anchor class B.

Optimise safety and productivity in working at heights with this 30 m horizontal lifeline. Its polyester rope of 10.5 mm with a fully cylindrical design ensures smooth sliding of trolleys, rings, and connectors, reducing friction and unnecessary stops. It incorporates as standard a non-removable carabiner 80111 (opening 19 mm, resistance 20 Kn) for quick and consistent connection; the opposite end is free for ballast connection, facilitating temporary installation on site. It is a robust and versatile class B solution, with excellent quality-price ratio and availability in various lengths to suit each project.

Usage suggestions: ideal for roofs, metal structures, and civil work; use it with certified PPE and absorbers, verify anchors and proper tension, and maintain periodic inspections.

Safety that moves with you.

Use cases:

- Installation of temporary lines on roofs during air conditioning or solar panel maintenance.

- Assembly and assembly of metal structures with protected horizontal displacement.

- Inspection and repair works on bridges, walkways, and mobile scaffolds.

- Packaging unit

- EN795B

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.