HORIZONTAL LIFELINE 20 m, polyester10.5 mm with carabiner

· 10.5 mm polyester rope, regarded as a portable anchorage device (class B anchoring device).

· Fully cylindrical: slides any element over it.

· At one end, non-removable 80111 carabiner, with 19 mm opening and 20 kN resistance.

· The other free end for ballast connection.

· Available in various sizes:

-5 m (Ref. 80250)

-10 m (Ref. 80251)

-20 m (Ref. 80252)

-30 m (Ref. 80253)

Class B anchor with integrated 80111 carabiner: quick, durable and reliable connection in demanding environments.

Optimises safety in working at heights with a robust and practical solution. Its 10.5 mm polyester rope, fully cylindrical, allows for smooth sliding of equipment and connectors, reducing friction and unnecessary stops. The non-removable 80111 carabiner (19 mm opening, 20 kN strength) provides quick assembly and reliable connection, while the free end facilitates weight joining according to the workstation configuration.

Design oriented towards performance (smooth sliding), Quality of materials (high-strength polyester) and an excellent cost-performance ratio for repetitive operations or temporary setups. As a class B anchoring device, it is ideal for portable configurations where efficiency is sought without sacrificing safety.

Usage suggestions:

- Select the appropriate anchorage points and verify the compatibility of connectors before tensioning the line.

- Combine with homologated harness and energy absorber and respect the expected fall factor.

- For specific sections, choose the ideal length from the available catalogue (5, 10, 20, and 30 m) to minimise sag and optimise mobility.

When the job demands constant safety and smooth movement, this lifeline responds with reliability and ease of use.

Use cases:

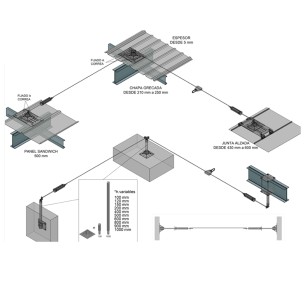

- Assembly and maintenance on roofs and rooftops with horizontal movement.

- Temporary installations on metal structures and scaffolding.

- Loading and unloading operations in docks and industrial warehouses.

- Packaging unit

- EN795B

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.