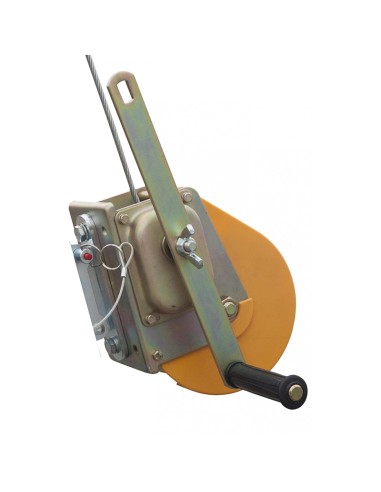

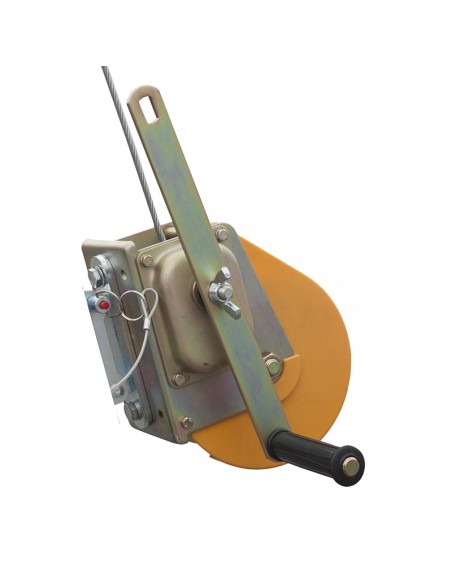

SAFETOP WINCH, 25 m cable for use with tripods

· Galvanised steel cable winder.

· Diameter: 6.3 mm.

· Functions as a rescue device

· Or as an ascent-descent equipment.

· Automatic brake device.

· Operation: manual.

· Crank with plastic handle.

· Automatic safety brake.

· Single-piece drum that winds the cable.

· Includes pulley.

· Includes claw for tripod leg positioning.

Robust design with monoblock drum and ergonomic crank delivering precise control, durability and reliability in the field.

The 25 m SAFETOP WINCH is designed for working at heights and in confined spaces where safety and control are non-negotiable. Its galvanised steel cable offers high resistance to corrosion, while the single-piece drum enhances durability and cable guidance, reducing wear.

Automatic braking technology adds an extra layer of safety in critical ascent and descent manoeuvres, and the manual operation with a plastic ergonomic handle crank allows smooth and precise control. Moreover, the inclusion of a pulley and tripod leg claw simplifies installation and ensures quick integration into existing rescue and access systems.

Usage suggestions: install it on tripods for confined space rescue, maintenance in wells or manholes, and vertical inspection tasks. Use it as a safety backup in lifting operations of persons, or as a main climbing/descending equipment when total control is required.

Control and safety at every metre.

Use cases:

- Confined space rescue using tripod and pulley system.

- Controlled ascent/descent operations in industrial maintenance.

- Vertical inspections in wells, manholes and treatment plants.

- Packaging unit

- EN1496

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.

You might also like