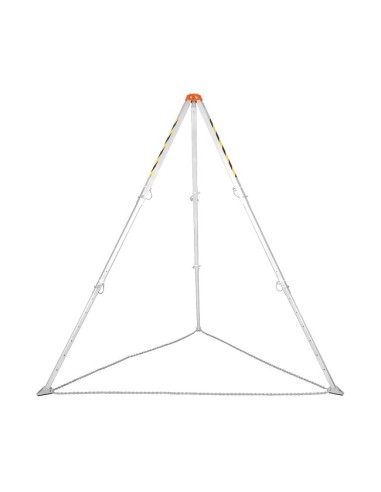

SAFETOP TRIPOD WITH MAX LEG OPENING OF 273 CM

· Portable tripod with telescopic legs

· Extendable legs.

· Tested for use by one person (140 kg), and with a load capacity of 500 kg.

· Steel feet with rubber washers.

· For flat surfaces.

· Spiked edges for slippery surfaces.

· Includes galvanised steel head with 4 anchor points.

· Adjustable aluminium legs (7 adjustment points).

· Safety chain linking the three legs.

· Tested for use by one person (140 kg).

· Load capacity of up to 500 kg.

· Portable and foldable.

· High visibility reflective bands.

· Working height: 143 cm.

· Opening diameter: 136-283 cm.

Robust design in aluminium and galvanised steel with 4 anchor points and 7 adjustment positions for maximum safety and versatility.

The SAFETOP TRIPOD WITH MAX LEG OPENING OF 273 CM is designed for those demanding a reliable and rapidly deployable temporary anchor point. Its adjustable aluminium legs (7 points), galvanised steel head with 4 anchors, and safety chain provide a solid and stable structure. The steel feet with rubber washers and the spiked edges optimise grip on both flat and slippery surfaces, while the reflective bands increase visibility in low-light settings.

With a load capacity of up to 500 kg and tested for a 140 kg user, it offers an exceptional balance between safety, portability, and quick installation. Utilise it for access and rescue tasks, industrial maintenance, and work at heights. Suggestions: combine it with certified lifelines, perform prior inspections of the support points, and transport the equipment folded to protect the metal components.

Security that unfolds with you.

Use cases:

- Access and rescue in confined spaces (wells, tanks, sewers).

- Industrial maintenance at height on flat or slippery surfaces.

- Construction and emergency interventions requiring temporary anchorage and rapid deployment.

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.