SELF-INSTALLABLE CABLE LIFELINE KIT FOR METAL SHEET 10m

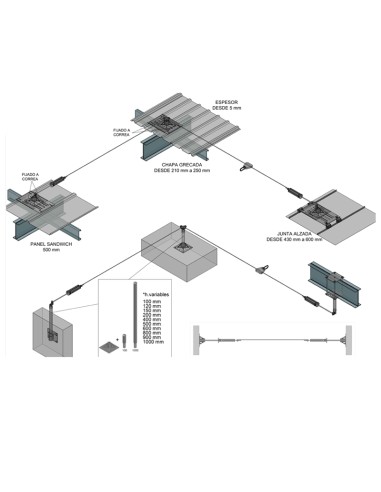

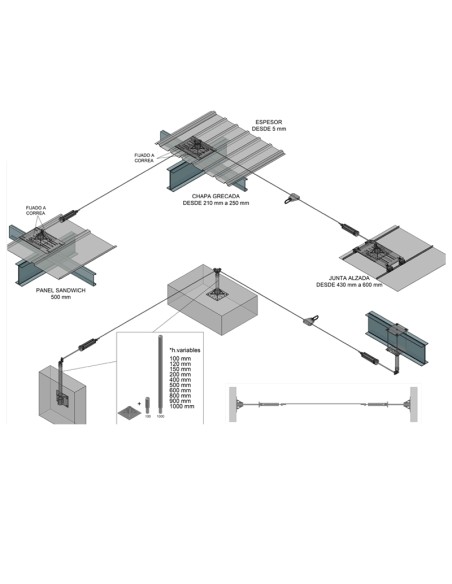

· Kit for any metal roof support, regardless of thickness (can be fixed with screws to the metal straps of the roof when sheet thicknesses are <0.6 mm)

· Suitable for up to 4 simultaneous users

· Easy cable assembly, only with a 19 mm wrench

· Supplied in 10, 20, and 30 m kits for straight lifelines

· The anchor line can optionally be supplied with a sliding device (Trolley)

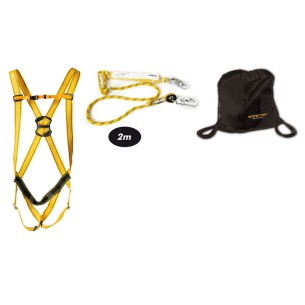

· Suitable for use as a safety line (EN354)

The SELF-INSTALLABLE CABLE LIFELINE KIT FOR METAL SHEET of 10 m is designed for work on metal roofs that require safety, efficiency and reliability. Its design allows anchorage on sheets of any thickness, even when screwing is necessary on thicknesses <0.6 mm, ensuring adaptability in multiple scenarios. It supports up to 4 simultaneous users, optimizing resources and time on site. Installation is straightforward with a single 19 mm wrench, reducing complexity, rework and mounting costs.

Available in 10, 20 and 30 m for straight lines and with an optional sliding trolley, it facilitates smooth and continuous movement along the line. Suitable for use as a safety line in accordance with EN354, it combines quality and technology with an excellent cost-benefit ratio, ideal for industrial maintenance, photovoltaics, and technical services at height.

Usage suggestions: plan anchor points and trajectory before assembling; check cable tension and strap condition; use compatible PPE and consider the sliding trolley when linear transit is frequent.

Use cases:

- Maintenance of metal roofs in industrial buildings and warehouses

- Installation and maintenance of photovoltaic systems, air conditioning, and antennas on metal sheets

- Inspection, gutter cleaning, and linear movement work on thin sheet metal roofs

- Packaging unit

- CEN/TS 16415

- OK

- EN795C

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.