TIBET size 'S', 3-point harness with extension sling

· Universal fall arrest harness tested for 140 Kg.

· Three attachment points.

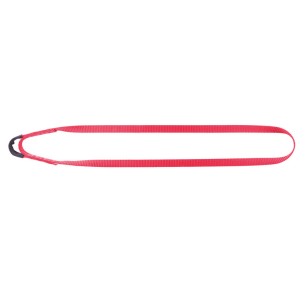

· Dorsal attachment ring for connecting the damping subset.

· 40 cm dorsal extension sling.

· Four closure and adjustment buckles.

· Two chest buckles and two on each thigh.

· Chest closure and adjustment buckle, joining the two shoulder straps.

· Straps adjustable to the user's body.

· Textile front loops.

· A subgluteal strap joining the two thigh straps.

· Applications: work at height, self-controlled descent, installation of collective protections, horizontal life line, ascent with vertical life line, etc.

It stands out for its adjustable ergonomics and certified quality which optimises performance in work at height.

The TIBET size S is the smart choice for professionals who demand safety, ergonomics and quality at a competitive price. Its 3 attachment points, with dorsal ring and textile front loops, offer versatility in anchorage for different work configurations. The 40 cm dorsal extension sling facilitates connection with absorbers and retractables without compromising mobility or posture.

The robust construction includes four closure and adjustment buckles, a chest buckle that stabilises the shoulder straps, and a subgluteal strap that improves load distribution, providing comfort during long shifts. Fully adjustable to the user's body, it ensures a precise and stable fit, key to the effectiveness of the fall arrest system tested up to 140 kg.

Usage suggestions: combine it with an EN 355 energy absorber, automatic closing connectors and certified horizontal or vertical life lines. Ideal for maintenance teams, installers and safety technicians who value outstanding quality-price ratio without compromising reliability.

Use cases:

- Work at height on structures and roofs

- Self-controlled descent and basic rescue

- Installation of collective protections

- Horizontal life line

- Ascent with vertical life line

- Packaging unit

- Anchor points

- 4

- Max load

- 140 Kg

- EN361

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.

You might also like