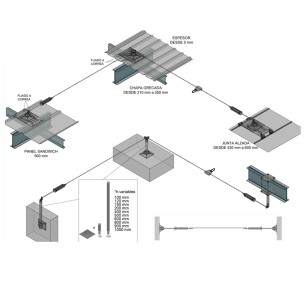

VERTICAL LIFELINE 20 m, without carabiners 12 mm

· 12 mm polyester rope.

· Available in various lengths:

-80350-10: 10 m

-80350-20: 20 m

-80350-30: 30 m

-80350-40: 40 m

-80350-50: 50 m

· At the upper end, an eyelet protected by a heat-shrink insulating sleeve.

· At the other end, a knot that serves as a stopper at the lower end, protected by a heat-shrink insulating sleeve.

· Suitable for use with fall-arrest sliding devices (altochuts).

Heat-shrink protections on both ends and compatibility with sliding devices for maximum efficiency and safety.

Designed to perform in demanding environments, this 20 m vertical lifeline combines the quality of 12 mm polyester with heat-shrink protection on both ends, extending the equipment's useful life and reducing maintenance. Its compatibility with fall-arrest sliding devices provides smooth and controlled mobility during ascents and descents, enhancing productivity without compromising safety. Thanks to its robust construction and a design intended for technical work, it offers an excellent value for money and consistent performance in temporary or permanent installations. Usage suggestions: select the appropriate certified sliding device for the rope diameter, check the certified upper anchor point before installation, and use the stopper knot as a safe limit for the travel at the lower end.

Choose technology and quality for each intervention at height: quick installation, reliable operation and support for your safety protocols.

Use cases:

- Work on fixed ladders and vertical accesses in industry and maintenance

- Assembly and inspection of scaffolding, towers and metal structures

- Telecommunications and energy operations on masts and poles

- Packaging unit

- EN353-2

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.