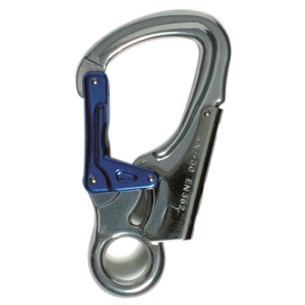

Aluminium Swivel Link with Double Bearing EN365

· Aluminium swivel link.

· Double bearing.

· Weight: 160 g.

· Maximum breaking load: 30 kN.

· Size: 55x108 mm.

Optimise your manoeuvres with a swivel link designed to perform in professional environments. Its double bearing reduces friction and maintains a constant rotation under load, protecting your systems from twisting and tangling. With an aluminium body for an excellent strength-to-weight ratio and a breaking load of 30 kN, it combines Technology and Quality in a compact format.

Sales arguments:

- Double bearing for smooth and controlled rotation.

- Aluminium construction: lightweight, strong and reliable.

- Optimised dimensions (55x108 mm) to integrate into multiple configurations.

Usage suggestions:

- Place it between the lifeline and the harness to prevent twisting during descents or lifts.

- Use it in pulleys and rescue systems to maintain alignment and efficiency of the assembly.

- Integrate the swivel into mobile anchors when there is a risk of load rotation or twisting.

Safe rotation, zero twisting.

Use cases:

- Working at height and technical rescue to prevent rope and sling twisting.

- Caving and arboriculture in manoeuvres with loads that tend to rotate.

- Industrial lifting and pulleys in maintenance and assembly of structures.

- Packaging unit

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.