RESCUER SERIES AS Safetop 15m and 140 kg load capacity for tripod 80371-AS

Rescuer for use with tripod 80371-AS.

· 1 user.

· Suitable for maximum load 140 Kg.

· Gear ratio 5:1.

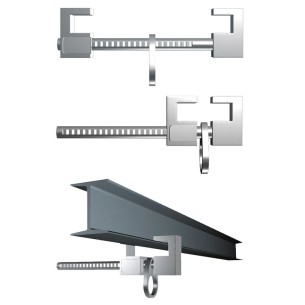

· Winch cable: stainless steel Ø 5 mm.

· Carabiner with fall indicator.

Available in 15 (80315-AS), 25 (80325-AS) and 35 metres (80335-AS).

Compatible with tripod 80371-AS and Ø5 mm stainless steel cable with carabiner and fall indicator for maximum reliability.

The Rescuer Series AS Safetop of 15m is designed to integrate seamlessly with tripod 80371-AS, offering precise hoisting and lowering manoeuvres in critical situations. Its 5:1 gear ratio significantly reduces effort, allowing smooth and consistent control of the rescue even under a maximum load of 140 kg. The Ø5 mm stainless steel cable ensures durability and corrosion resistance in demanding environments, extending the equipment's lifespan and maintaining reliable performance. The carabiner with fall indicator adds an essential layer of safety and traceability, helping to verify the system's condition before each intervention. With a robust design oriented to real work, this equipment offers excellent value for money and the confidence of a brand with a broad catalogue (options of 25 and 35 m available). Usage suggestions: inspect the fall indicator before each operation, check the anchorage to the tripod 80371-AS and perform tension tests without load; operate with a single user respecting the 140 kg limit. Ideal for rescue protocols in confined spaces, industrial maintenance, and civil works where speed and precision are key. Elevate safety, reduce effort.

Use cases:

- Rescue in confined spaces in industrial plants, sanitation, and treatment facilities with tripod 80371-AS.

- Interventions in wells, silos, and tanks for controlled hoisting/lowering of a user.

- Maintenance and rescue operations in civil works and energy where corrosion-resistant equipment is required.

- EN1496

- OK

- AS SERIES

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.