HORIZONTAL LIFELINE 20 m, adjustable webbing for 3 users

· Type B horizontal lifeline.

· For work requiring frequent horizontal movement.

· Total length: 20 m. Adjustable.

· Width of webbing: 35 mm. Static resistance: 29 Kn.

· Both ends manufactured in loop.

· Loops leather-reinforced to resist wear.

· The equipment is valid for three users at once

· Anchor point requirement: 30 Kn (for 3 users).

· Adjustable in length via the tensioner.

· Force required to tension: 0.5-1.5 Kn.

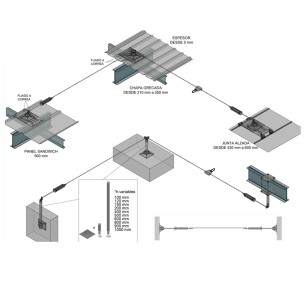

· Its structure is composed of:

· A tensioner made of galvanised steel. Includes ratchet with plastic handle.

· A polyester webbing 35 mm wide x 19 m long, in contrasting colour, connected to the metal tensioner. The main webbing is presented rolled up with a strip to prevent unraveling. To open it, just activate a "backpack" type clasp.

· A polyester joining strap, 50 mm wide and 0.7 m long. At the end includes a loop with leather protection.

35 mm webbing and 29 Kn resistance with galvanised steel tensioner requiring minimal tensioning force.

Optimise your work at height with a 20 m adjustable horizontal lifeline prioritising safety, agility, and durability. Its 35 mm polyester webbing and static resistance of 29 Kn, combined with leather-reinforced loops, provides reliable performance even in demanding environments. The galvanised steel tensioner with ratchet and plastic handle enables precise tensioning with just 0.51.5 Kn of effort, reducing installation times and improving operator ergonomics.

Designed for three simultaneous users, it is a robust solution with an excellent cost-benefit ratio for work involving frequent horizontal movements. The adjustable length and loop-manufactured ends simplify assembly between 30 Kn capable anchors.

Usage suggestions: ensure anchor points comply with 30 Kn, tension within the recommended range, keep the webbing free of sharp edges, and use compatible fall arrest PPE.

20 metres of confidence for three.

Use cases:

- Work on roofs and metal structures with continuous horizontal movement

- Industrial maintenance on walkways, overhead cranes and process lines

- Scaffold assembly and installation tasks on façades or warehouses

- Packaging unit

- EN795B

- OK

- CEN/TS 16415

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.

You might also like