TELENO XXL, 5p seat harness quick buckles

Full-body suspension harness with EVA belt and quick buckles

·Suitable for suspension work.

·Certified for rescue (EN1497).

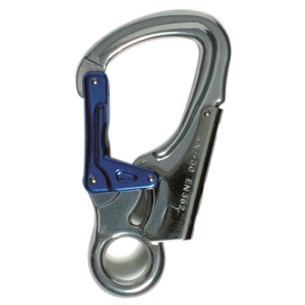

·Adjustable quick-release buckles

·Adjustable padded leg loops

·Ergonomic dorsal pad and shoulders

·Adjustable shoulder straps

·Protected rings for hanging accessories

·Highly comfortable and lightweight design

·Easy placement and adjustment

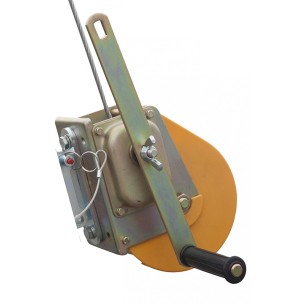

·Screw-lock central carabiner

·Applications: suitable for work at height or on slopes in construction, civil engineering, mining, and quarrying, to prevent operators from potential falls.

EN361 EN358 EN813 EN1497

EVA ergonomics, padding, and certifications EN361/EN358/EN813/EN1497: professional performance with lightweight design.

TELENO XXL is a 5-point seat harness designed for work at height that requires safety and agility. Its EVA belt, padded leg loops, and ergonomic shoulder design reduce fatigue and increase stability during demanding shifts.

The quick buckles and multiple adjustment points facilitate precise and swift placement, while the screw-lock central carabiner and protected rings optimise the use of ropes and accessories. With a focus on Quality, Design, and Ergonomics, it meets EN361, EN358, EN813, and EN1497 for suspension work and rescue manoeuvres.

Suggested for construction, industrial and wind maintenance, rope access, and rescue units that demand efficiency and reliability.

Secure suspension, superior comfort.

Use cases:

- Rope access and suspension work in industrial and wind maintenance.

- Operations on inclined structures in construction and civil engineering.

- Interventions in mining and quarries, and rescue manoeuvres certified EN1497.

- Packaging unit

- EN361

- OK

- EN1497

- OK

- EN358

- OK

- EN813

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.