MAXIROLL, Retractable 30m cable 5.5mm, Horizontal and Vertical use 140Kg

· Retractable cable lifeline.

· Galvanised steel.

· In lengths of 6, 10, 15, 20, 25, and 30 m.

· Tested for vertical and horizontal use.

· Cable diameter is 4.8 mm braided.

· Loop finish.

· Maximum working load: 140 Kg.

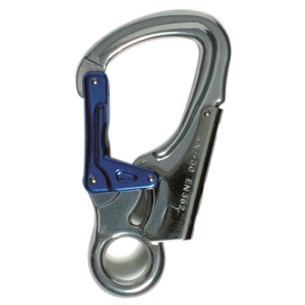

· Connected to a quick-release carabiner.

· Oval steel holder.

· Hole 30 mm x 18 mm.

· The housing is thermoplastic with a diameter of 21 cm.

· Reduced weight and dimensions.

· Its lightness reduces operator fatigue.

· Easy to transport.

· The lower carabiner is a rotary head swivel ring.

· Prevents the cable from twisting if the operator turns.

· Avoids cable twists, extending its life.

· Includes handle for easy transport and placement.

Galvanised steel cable and lightweight thermoplastic housing: professional robustness with less fatigue and comfortable transport.

MAXIROLL is designed to maximise performance in demanding environments. Its retractable operation offers a smooth and constant response, while the galvanised steel cable ensures durability and abrasion resistance. Certification for horizontal and vertical use, along with a capacity of up to 140 kg, provides real versatility in construction sites, industrial maintenance, and rooftop work. The thermoplastic housing, compact in size and optimised in weight, improves ergonomics and reduces daily operator fatigue. The lower carabiner with a rotating head avoids cable twists, enhancing safety, prolonging the equipment's lifespan, and minimising maintenance downtime. Its integrated handle facilitates agile transport and installation at different anchorage points.

Usage suggestions: combine MAXIROLL with certified harnesses and suitable anchorage points; keep the equipment clean and check the system before each workday; leverage its performance in long routes and frequent movements, where the retractable offers maximum efficiency.

30 m of safety, 0 twists.

Use cases:

- Work on rooftops, roofs, and temporary lifelines

- Assembly and maintenance of metal structures and industrial facilities

- Operations in wind parks, bridges, and platforms with fall risk

- Packaging unit

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.