30 m HORIZONTAL LIFELINE, adjustable for 3 users

· Type B horizontal lifeline with backpack.

· For tasks requiring frequent horizontal movement.

· Total length: 30 m. Adjustable.

· Strap width: 35 mm.

· Loop manufactured on both ends.

· Suitable for use by 3 operators simultaneously.

· Length adjustable through the tensioner.

· Its structure consists of:

· A tensioner made of galvanised steel. Includes ratchet with plastic handle.

· A 35 mm wide x 19 m long polyester strap, in contrast colour, connected to the metal tensioner. The main strap is presented rolled with a strip to prevent unrolling. To open, simply trigger a backpack-type clasp.

· A 50 mm wide and 0.7 m long polyester connecting strap. Includes loop with leather protection at the end.

· Standard EN170

Galvanised steel tensioner and 35 mm strap for quick adjustment, high durability and excellent value for money.

Optimise safety in horizontal movements with a 30 m Type B lifeline that installs and adjusts in minutes. Its compact design with backpack makes transport and deployment easy, reducing downtime on site. The galvanised steel ratchet tensioner technology maintains stable tension, while the 35 mm polyester strap offers resistance and long life in demanding environments. Thanks to the looped ends and connecting strap, it allows for versatile anchors and quick configuration. Approved for 3 simultaneous users, it allows teams to coordinate without sacrificing safety or productivity. Recommendations: verify anchorage point strength, keep the strap clean and dry, and use compatible PPE in accordance with the indicated standard. A high-quality solution with a very competitive quality-price ratio for maintenance, construction, and assembly.

Use cases:

- Work on roofs, walkways, and edges of slabs with frequent movement.

- Industrial maintenance in warehouses, process plants, and production lines.

- Assembly of metal structures, scaffolding, and operations on trucks/cisterns.

- Packaging unit

- EN795B

- OK

- CEN/TS 16415

- OK

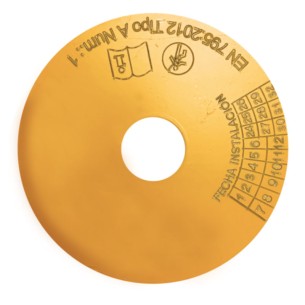

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.