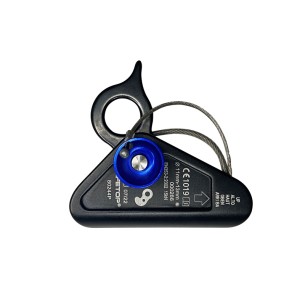

PULLEY PinLock, with lock for ropes up to 18 mm EN12278

· Forged aluminium pulley for tripod.

· Weight: 1.4 kg.

· Casing material: forged aluminium

· Main shaft material: stainless steel

· Dimensions: 176x96x88 mm

· MBS: 100 kN

· WLL: 20 kN

· Safety factor 5:1

· Permitted rope diameter: <18 mm

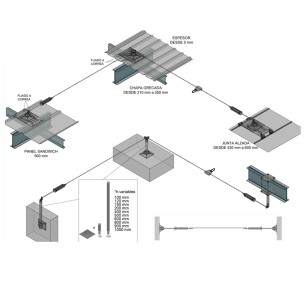

· APPLICATIONS Tripod pulley.

The PinLock PULLEY combines robust design and safety-oriented technology for critical operations with tripod. Its forged aluminium casing and stainless steel main shaft ensure durability and load precision. The PinLock locking system minimises risks of accidental opening under tension, providing confidence to the technical user. With MBS of 100 kN, WLL of 20 kN and EN 12278 certification, it offers an optimal balance between reliability, compact dimensions and contained weight (1.4 kg). Usage suggestions: use ropes up to 18 mm, check the condition of the equipment before each intervention, and combine with certified tripods and anchors to form safe and efficient pulley systems.

Use cases:

- Controlled hoisting and descent with tripod in confined spaces

- Industrial rescue and evacuation with pulley systems

- Maintenance in wells, sewers, and treatment plants with ropes up to 18 mm

- Packaging unit

- EN12278

- OK

Is the inspection of fall-arrest PPE mandatory?

All fall-arrest equipment must undergo a mandatory annual inspection starting from the date of its first use, in accordance with the UNE EN 365:2005 standard. This inspection ensures that the equipment maintains its safety conditions. The user must record the date of first use in the corresponding inspection sheet.

Inspection frequency: Once per year.

Who is authorized to inspect the equipment?

Inspections of Safetop fall-arrest equipment can only be carried out by Safetop or by a Safetop-authorized person.

- Safetop-certified distributors

Only distributors trained and certified by Safetop are authorized to perform inspections of our PPE. This specialized training enables them to identify defects, monitor material condition, and issue valid inspection reports. - Safetop inspection technical service

We offer our own technical inspection service for fall-arrest equipment, exclusively for distributors. End users should not send equipment directly; instead, they must manage it through their supply partner. - Safetop-authorized personnel

Safetop provides technical inspection courses for suppliers, enabling them to become authorized inspection centers.

Safetop Monitor

Manage your equipment, inspections, and expiration dates with our Safetop Monitor application. Centralize technical documentation, inspection notifications, and PPE tracking all in one place.

You might also like